Anyone who has ever worked in a dyehouse knows the feeling – fabric comes out of the dye machine and there are spots, imperfections, and defects on the fabric. What went wrong? Was something improperly loaded? Is there a problem with the dyebath formula?

Or…could it be something simpler?

A clean textile wet processing machine helps to ensure the production of first quality yarns and fabrics but using a dirty machine decreases productivity, increases costs, and creates goods with defects.

Off-standard fabric hits a mill where it hurts the most: the bottom line. Mills spend time and money developing procedures and recipes, but a critical component for preparation, dyeing, and finishing is often overlooked: a proper machine cleaning procedure.

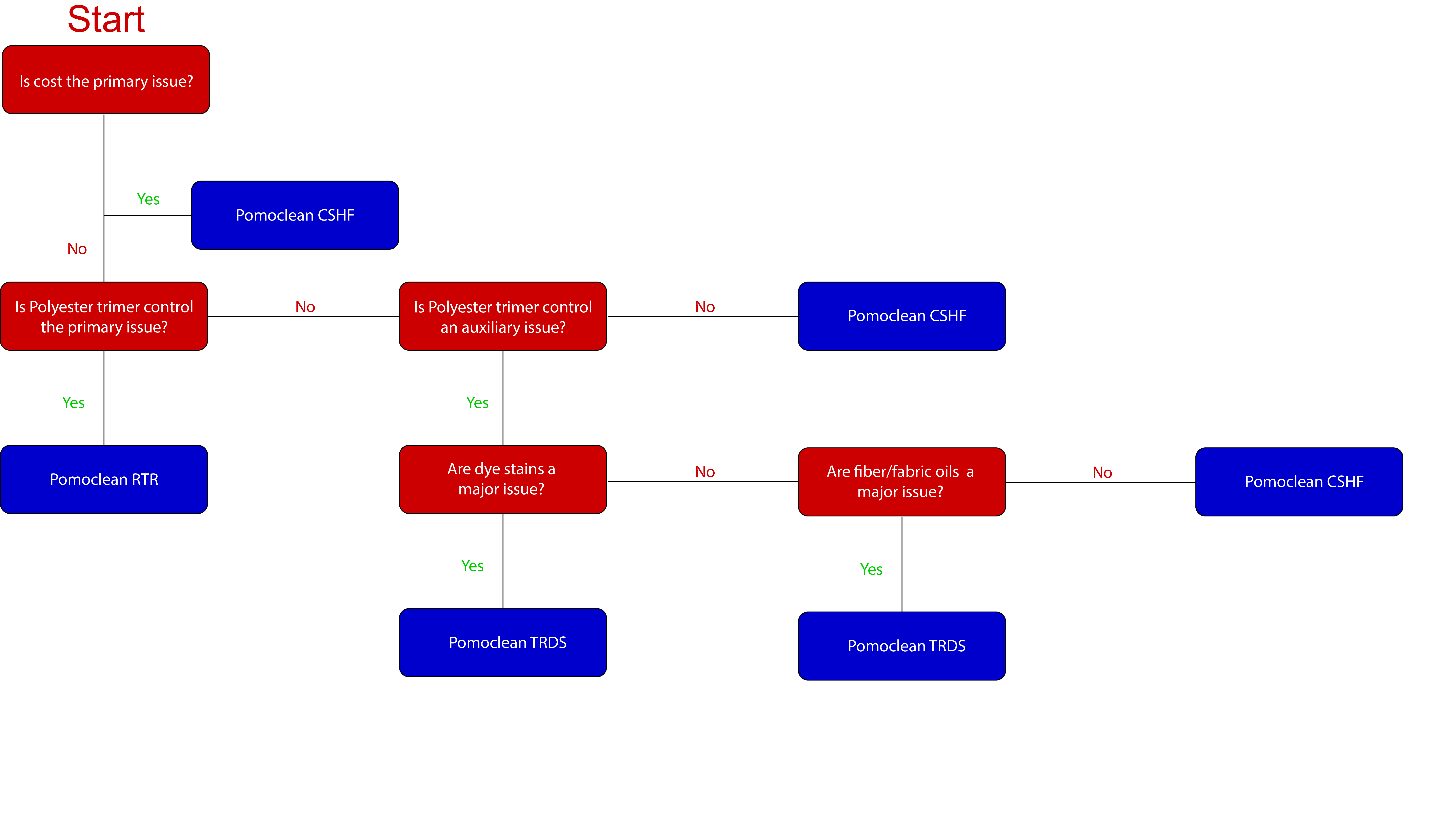

No two mills or products are alike so, a machine cleaner should be selected to address unique process impurities encountered during production. Questions can be asked to determine the type of chemistry that will fit best to any processing situation:

Which critical functions must be a part of your cleaning package?

- High Foaming?

- Trimer Removal?

- Dye stain removal?

- Detergency?

- Emulsification/solubilizing agents?

Piedmont Chemical Industries has formulated a range of specialized machine cleaners to address the challenges faced by today’s dyer/finisher. At Piedmont, we’ve developed a decision tree for deciding which machine cleaner to use, so you can save your time and energy for doing what’s most important: developing top-quality textile products.